TBC Ingredients ApS

From coconut to ingredients

While there are some large plantations with integrated operations, copra remains primarily a smallholder crop. The major producing countries are the Philippines, Indonesia and India.

Copra production begins with the coconut plantations. Coconut trees are generally spaced 9 m (30 ft) apart, allowing a density of 100-160 coconut trees per hectare.

Our

Coconut products

From coconut to ingredients continued…

Botanically the coconut fruit is a drupe, not a true nut.

A full-sized coconut weighs about 1.4 kilograms. It takes around 6000 full-grown coconuts to produce a tonne of copra.

Desiccated coconut, plain – in the grades: Fine, medium, threads and chips.

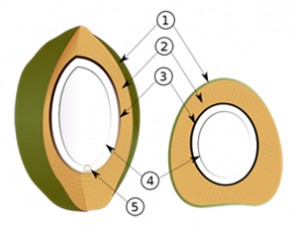

The shell

Shell of the seed

Layers of the coconut fruit

(1) Exocarp / Epicarp

(2) Mesocarp

(3) Endocarp

(4) Endosperm

(5) Embryo

Within the shell is a single seed. When the seed germinates, the root of its embryo pushes out through one of the eyes of the shell. The outermost layer of the seed, the testa, adheres to the inside of the shell. In a mature coconut, a thick albuminousendosperm adheres to the inside of the testa. This endosperm or meat is the white and fleshy edible part of the coconut. Although coconut meat contains less fat than many oilseeds and seeds such as almonds, it is noted for its high amount of medium-chain saturated fat. About 90% of the fat found in coconut meat is saturated, a proportion exceeding that of foods such as lard, butter and tallow. There has been some debate as to whether or not the saturated fat in coconuts is healthier than other forms of saturated fat.

Coconut

Process

The endosperm surrounds a hollow interior space, filled with air and often a liquid referred to as coconut water (distinct from coconut milk). Immature coconuts are more likely to contain coconut water and less meat. They are often sold with a small portion of the husk cut away to allow access to the coconut water. Young coconuts used for coconut water are called tender coconuts. The water of a tender coconut is liquid endosperm. It is sweet (mild) with an aerated feel when cut fresh. Depending on its size a tender coconut contains 300 to 1,000 ml of coconut water.

The meat in a green young coconut is softer and more gelatinous than that in a mature coconut – so much so that it is sometimes known as coconut jelly. When the coconut has ripened and the outer husk has turned brown, a few months later, it will fall from the palm of its own accord. At that time the endosperm has thickened and hardened, while the coconut water has become somewhat bitter.

When the coconut fruit is still green, the husk is very hard, but green coconuts only fall if they have been attacked by molds or other blights.

By the time the coconut naturally falls, the husk has become brown, the coir has become drier and softer,

On the same inflorescence, the palm produces both the female and male flowers. The female flower is much larger than the male flower. Flowering occurs continuously. Coconut palms are believed to be largely cross-pollinated, although some dwarf varieties are self-pollinating.

The liquor can now be cooled and molded into blocks known as unsweetened baking chocolate (bitter chocolate). It can be shipped in solid form for further processing elsewhere in the world.

Chocolate liquor contains roughly 53 percent cocoa butter (fat), about 17 percent carbohydrates, 11 percent protein, 6 percent tannins, and 1.5 percent theobromine.

Production

Copra has traditionally been grated and ground then boiled in water to extract coconut oil. Nowadays, the process of coconut oil extraction is done by crushing copra to produce coconut oil (70%); the by-product is known as copra cake or copra meal (30%).

Once the oil is extracted, the remaining coconut cake is 18-25% protein but contains so much dietary fiber it can not be eaten in large quantities by humans. Instead it is normally fed to ruminants.

Making

Copra

Making copra – removing the shell, breaking up, drying – is usually done where the coconut palms grow. Copra can be made by smoke drying, sun drying, or kiln drying. Sun drying requires little more than racks and sufficient sunlight. Halved nuts are drained of water, and left with the meat facing the sky. They can be washed to remove mold-creating contaminants.

After two days the meat can be removed from the shell with ease, and the drying process is complete after three to five more days (up to seven total).

This process can also be reversed, partially drying the copra in the kiln and finishing the process with sunlight. There are advantages and disadvantages to both – starting with sun drying requires careful inspection to avoid contamination with mold while starting with kiln-drying can harden the meat and prevent it from drying out completely in the sun. In India, small but whole coconuts can be dried over the course of eight months to a year, and the meat inside removed and sold as a whole ball.

Oil

Coconut oil

Coconut oil is an edible oil extracted from the kernel or meat of matured coconut harvested from the coconut palm. Throughout the tropical world, it has provided the primary source of fat in the diets of millions of people for generations. It has various applications in food, medicine, and industry. Coconut oil is very heat-stable, which makes it suited to methods of cooking at high temperatures like frying. Because of its stability, it is slow to oxidize and, thus, resistant to rancidity, lasting up to two years due to high saturated fat content. Numerous governmental agencies and medical organizations recommend against the consumption of significant amounts of coconut oil due to the high saturated fat content.

Coconut oil can be extracted through “dry” or “wet” processing. Dry processing requires the meat to be extracted from the shell and dried using fire, sunlight, or kilns to create copra. The copra is pressed or dissolved with solvents, producing the coconut oil and a high-protein, high-fiber mash. The mash is of poor quality for human consumption and is instead fed to ruminants; there is no process to extract the protein from the mash. The preparation and storage of copra often occurs in unhygienic conditions, which results in a poor-quality oil that requires refining before consumption. A considerable portion of the oil extracted from copra is lost due to spoilage, due to consumption by insects and rodents, and during the extraction process.

All-wet process involves raw coconut rather than dried copra, using the protein in the coconut to create an emulsion of the oil and water. The more problematic step is breaking up the emulsion to recover the oil. This used to be done through lengthy boiling, but this produces a discolored oil and is not economical. Modern techniques use centrifuges and various pre-treatments including cold, heat, acids, salts, enzymes, electrolysis, shock waves, or some combination of them. Despite numerous variations and technologies, wet processing is less viable than dry processing due to a 10-15% lower yield, even compared to the losses due to spoilage and pests with dry processing. Wet processes also require an expensive investment of equipment and energy, incurring high capital and operating costs.

harvesting

Proper harvesting

Conventional coconut oil uses hexane to extract up to 10% more oil than just using rotary mills and expellers. The oil is then refined to remove certain free fatty acids, in order to reduce susceptibility rancidification. Other processes to increase shelf life include using copra with a moisture content below 6%, keeping the moisture content of the oil below 0.2%, heating the oil to 130–150 °C and adding salt or citric acid. Virgin coconut oil (VCO) can be produced from fresh coconut meat, milk or residue.

A thousand mature coconuts weighing approximately 8,500 kilograms yields around 170 kilograms of copra from which around 70 liters of coconut oil can be extracted.

Our

RBD

The dried copra is placed in a powerful hydraulic press with added heat, and the oil is extracted. This yields up practically all the oil present, amounting to more than 60% of the dry weight of the coconut. This “crude” coconut oil is not suitable for consumption because it contains contaminants and must be refined with further heating and filtering.

Another method for extraction of a “high-quality” coconut oil involves the enzymatic action of alpha-amylase, polygalacturonases, and proteases on diluted coconut paste.

Unlike virgin coconut oil, refined coconut oil has no coconut taste or aroma. RBD oil is used for home cooking, commercial food processing, and cosmetic, industrial, and pharmaceutical purposes.

Our

Hydrogenation

In the process of hydrogenation, unsaturated fats (monounsaturated and polyunsaturated fatty acids) are combined with hydrogen in a catalytic process to make them more saturated. Coconut oil contains only 6% monounsaturated and 2% polyunsaturated fatty acids. In this process, some of these are transformed into trans fatty acids.

If hydrogenation is taken to completion (i.e., the oil is “fully hydrogenated”), there are no trans fats remaining. There are no “natural” cis fats, either. Only partial hydrogenation produces trans fats.

Our

Fractionation

Our products

Desiccated Coconut

Our products

Desiccated Coconut

Oil products packing

Coconut consentrate packing

Coconut milk/cream packing

Coconut milk powder packing

Desiccated coconut packing

Desiccated coconut are in stock